TL;DR

- Amazon’s rising FBA fees make effective inventory management crucial for profitability.

- Stockouts lead to lost rankings, unhappy customers, and decreased sales potential.

- Overstocking results in high storage fees, ties up cash flow, and reduces IPI scores.

- Use inventory tools, regular audits, and track lead times to avoid costly mistakes.

- Manage inventory to improve cash flow, maintain IPI, and secure better growth.

- Avoid these common mistakes and let eStore Factory help you master inventory control.

With FBA fees increasing and Amazon introducing new fees every year, effective inventory management has never been more important.

While some slip-ups may seem small, they do compound over time.

And those small mistakes? They eat into your profits. Hurt your ranking. Damage your growth potential.

So how are you going to keep those mess-ups to a minimum?

Let’s find out!

But first, we’ll understand:

Quick guide

- Why is inventory management essential?

- Different methods of inventory management

- 1) Just-in-Time (JIT)

- 2) ABC analysis

- 3) Dropshipping

- 4) Bulk shipments

- 5) First-in, first-out (FIFO) and Last-in, first-out (LIFO)

- 6) Economic Order Quantity (EOQ)

- 7) Minimum Order Quantity (MOQ)

- Recent Amazon updates that make inventory management a priority

- Top inventory mistakes Amazon sellers must avoid

- #1: Overstocking inventory

- #2: Understocking and running out of stock

- #3: Allowing inventory to become stranded

- #4: Holding aged inventory

- #5: Neglecting perishable inventory

- #6: Skipping regular inventory audits

- #7: Ignoring safety stock

- #8: Failing to use inventory tools

- #9: Holding excess inventory too long

- #10: Ignoring seasonal trends

- #11: Mishandling returns

- #12: Failing to track supplier lead times

- #13: Failing to sync inventory across platforms

- #14: Not building relationships with suppliers

- #15: Ignoring your sell-through rate

- End inventory headaches, embrace success

Why is inventory management essential?

You might think: everyone goes out of stock once in a while, and everyone pays storage fees now and then—what’s the harm in that?

But it isn’t as small a deal as you think.

Most sellers we know get obsessed with keeping their PPC campaigns running hot 24/7. They stress over account health metrics until everything is perfect. And yes, those things are crucial for staying afloat on Amazon.

But inventory management? It’s just as crucial.

If you don’t manage your inventory well, here’s what can happen:

1) Stockouts lead to lost ranking: When you run out of stock, Amazon lowers your Best Sellers Rank. Why? Because Amazon wants to promote products that are consistently available. Each day you’re out of stock, competitors get more sales, higher visibility, and improved rankings. Your listing loses its organic reach. It’s like a chain reaction, and getting that lost ranking back is hard.

2) Stockouts disappoint customers: Customers come to Amazon expecting quick, seamless shopping. When they see your product is out of stock, they move on. They buy from your competition. And once they’ve found an alternative, they may never come back. You’re not just losing a sale; you’re losing a potential lifetime customer.

3) Excess inventory drains your profits: Overstocking is just as dangerous. When products sit for too long, they incur storage fees, especially if you’re using FBA. Amazon isn’t a warehouse for storing goods for extended periods. Monthly fees add up fast, and if inventory gets stuck for more than 271 days, expect an aged inventory surcharge that slashes profit margins even more.

4) High storage costs choke your cash flow: Holding too much inventory ties up your cash. That’s money you could use to improve listings, boost marketing, or expand product lines. Instead, it sits in a fulfilment centre, accumulating fees. You might think, “At least I have stock available,” but what you have is dead money.

5) Stranded inventory goes nowhere: Sometimes, products end up “stranded”—sitting in Amazon’s fulfilment centres without an active listing. You can’t sell these products, yet they still take up space and incur fees. Worse still, they contribute nothing to your sales volume, while costing you heavily in terms of storage.

6) Low sell-through rates impact IPI scores: Inventory Performance Index (IPI) scores are critical to maintaining inventory capacity. Overstocking or having stranded inventory negatively impacts your IPI. A lower score means less inventory capacity, and ultimately less flexibility to manage your stock as you need.

But if you do manage your inventory properly, here’s what you can expect:

1) Maximise profitability with balanced inventory: With effective management, you maintain just the right amount of stock. Not too little, not too much. This helps you avoid both stockouts and excess storage fees. It’s about optimising your cash flow—so your money works for you, not against you.

2) Keep customers happy and coming back: When your products are consistently available, customers learn they can count on you. You become their go-to option, not just once, but repeatedly. Reliable availability builds brand loyalty. Customers don’t need to look elsewhere; they trust that your products will be there when they want them.

3) Lower fees mean higher margins: Avoiding overstocking means fewer fees—both for storage and surcharges. Managing your inventory efficiently keeps costs down, allowing you to maintain healthier profit margins. More profits mean more opportunities for growth, reinvestment, and expansion.

4) More control over your growth strategy: Managing inventory properly gives you the freedom to plan. Whether it’s scaling during peak seasons or launching a new product, having control over your inventory means you have control over your growth. You’re not held back by supply chain disruptions or limited by poor cash flow. You can make bold moves with confidence.

5) Improve your IPI and expand your storage capacity: A high IPI score gives you access to more storage and lower costs. Better inventory management means a higher score, and that means you can grow without worrying about Amazon reducing your storage limits. Expansion becomes possible, and Amazon rewards you with better visibility and lower overheads.

6) Better demand forecasting for the future: When you manage inventory well, you can accurately forecast demand. You have the data you need to make smart decisions—when to reorder, how much to stock, and which products to promote. Forecasting reduces guesswork, improves your cash flow, and ultimately keeps your business running smoothly.

Different methods of inventory management

When it comes to managing inventory, you have several methods to choose from. Each approach has unique benefits and challenges, depending on your business needs.

1) Just-in-Time (JIT)

With Just-in-Time (JIT) inventory, you order products just before you need them. You keep minimal stock on hand, reducing storage costs significantly. JIT ensures fresh products and minimises waste. However, it requires precise timing and strong supplier reliability. A delay anywhere in the supply chain can lead to stockouts, so only adopt JIT if you trust your suppliers 100%.

2) ABC analysis

ABC analysis helps categorise your inventory by value and priority. Products are divided into three groups:

- A items: These are your best sellers. They generate the most revenue and need constant monitoring to avoid stockouts.

- B items: Moderately important products. They contribute to sales but don’t have the high revenue impact of A items.

- C items: Low-cost, low-importance products. They sell sporadically and don’t drive much profit.

Using ABC analysis, you focus your resources where they matter most—ensuring A items are always available while optimising costs for B and C items.

3) Dropshipping

Dropshipping eliminates the need for you to hold inventory. When customers place orders, you buy products from a supplier who ships them directly. Dropshipping means you don’t worry about warehousing, and it’s an easy way to start selling. However, it offers lower profit margins, and you have less control over quality or shipping times. To succeed with dropshipping, choose reliable suppliers who can ensure customer satisfaction.

4) Bulk shipments

Bulk shipments involve ordering large quantities at once. This strategy often comes with supplier discounts and lower shipping costs, boosting profitability. But there are downsides: it requires significant storage space and ties up cash in inventory that may not sell immediately. Bulk ordering is ideal if you know your product demand is stable and have the resources to manage large stock levels.

5) First-in, first-out (FIFO) and Last-in, first-out (LIFO)

FIFO and LIFO refer to how inventory is managed through the supply chain:

FIFO: First-in, first-out means you sell your oldest stock first. This approach is especially critical for perishable goods, as it ensures that products don’t expire on shelves. FIFO also helps you manage inventory effectively by delivering the freshest items to customers.

LIFO: Last-in, first-out means your most recent stock gets sold first. LIFO can help you save on costs during times of inflation. However, it’s less suitable for perishable products, as the older stock might sit unsold, which can lead to loss.

6) Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) helps determine the optimal amount to order. EOQ is about balancing your order size so you minimise storage and order costs. This method calculates the ideal order quantity using factors like carrying costs, demand, and lead time. EOQ ensures you don’t tie up too much money in inventory, while still keeping enough stock to fulfil orders efficiently.

7) Minimum Order Quantity (MOQ)

Minimum Order Quantity (MOQ) refers to the smallest number of units a supplier will sell. Knowing your suppliers’ MOQ helps you plan appropriately to meet their minimum requirements. This prevents delays and keeps your supply chain running smoothly. When you understand MOQ, you avoid wasting time negotiating quantities and ensure you’re aligned with supplier needs.

| Method | Description | Pros | Cons | Best for |

| Just-in-Time (JIT) | Order products only when needed. | Low storage costs, fresh products. | The risk of stockouts relies on reliable suppliers. | Businesses with reliable supply chains and quick restock cycles. |

| ABC Analysis | Categorise inventory into A, B, C based on importance. | Prioritises resources, and better monitoring of critical items. | Requires consistent analysis. | Sellers with a diverse inventory, need to focus on top-performing items. |

| Dropshipping | No stock holding, the supplier ships directly to the customer. | No storage/handling costs, low risk. | Lower profit margins, and less control over quality and delivery. | Startups or sellers with limited capital looking to minimise risk. |

| Bulk Shipments | Purchase inventory in large quantities. | Lower per-unit costs, and shipping discounts. | High storage costs, tie up capital. | Sellers with stable, predictable product demand and storage capacity. |

| First-In, First-Out (FIFO) | Sell the oldest stock first. | Ideal for perishable goods, reduces waste. | Less flexible during cost fluctuations. | Businesses selling perishable or time-sensitive products. |

| Last-In, First-Out (LIFO) | Sell the most recent stock first. | Helps during inflation to manage costs. | Can leave old inventory unsold. | Businesses managing inflation-sensitive costs, not dealing in perishables. |

| Economic Order Quantity (EOQ) | Optimal order size calculation. | Reduces total inventory costs. | Complex to calculate manually. | Businesses need to minimise both holding and ordering costs. |

| Minimum Order Quantity (MOQ) | Minimum units required by the supplier. | Prevents supply chain delays. | Limits flexibility, can result in overstock. | Sellers working with new suppliers or those needing to meet minimum requirements. |

Each of these methods has distinct advantages and challenges. The key is to select the one that fits your business needs and helps you manage inventory efficiently to keep customers happy.

Whether you choose a lean method like JIT, a simple system like FIFO, or focus on bulk shipments to save costs—getting it right means fewer headaches, lower costs, and better profitability.

Recent Amazon updates that make inventory management a priority

Update 1: FBA capacity limits (March 2023 update)

On March 1, 2023, Amazon replaced the weekly restock and quarterly storage volume limits with FBA capacity limits.

With FBA capacity limits, each type of storage in your account (e.g., standard size, oversize) gets its specific limit. Amazon sets these limits during the third week of every month and provides estimates for the next three months to help you plan. This means you can forecast and strategize based on your storage needs, reducing surprises and optimising space.

For new professional sellers, capacity limits do not apply immediately. Amazon first measures your inventory performance. Accounts that are at least 39 weeks old have capacity limits based on their Inventory Performance Index (IPI) score. Simply put, a higher IPI score means more storage capacity. That’s why managing your inventory efficiently directly affects your ability to grow on Amazon.

Need more capacity? You can request it by paying a “reservation fee.” This fee is competitive. Sellers bid against each other, and those who bid higher get priority. But there’s a silver lining: you can offset the reservation fee completely if the new inventory sells through. Essentially, if you manage your stock well, you avoid the extra cost entirely.

To stay on top of these limits, Amazon offers the Capacity Monitor in the new FBA dashboard. It’s where you get a clear view of your FBA business, capacity usage, and estimated limits for upcoming months. It’s a critical tool for anyone serious about inventory control.

Update 2: Low-level inventory fee (April 2024 update)

Effective April 1, 2024, Amazon introduced a low-level inventory fee aimed at sellers who consistently keep low inventory relative to customer demand. This fee is for standard-sized products with inventory levels below 28 days of supply. If both short-term (30 days) and long-term (90 days) inventory metrics fall below this threshold, the fee kicks in. Amazon wants sellers to maintain enough stock to meet demand swiftly.

Amazon’s reasoning is straightforward. Low inventory impacts the efficiency of their network, increasing shipping costs and slowing delivery. They want sellers to maintain healthy stock levels to ensure quick fulfilment and a positive customer experience. For sellers, that means keeping track of both long-term and short-term supply levels to avoid unexpected costs. These fees are added to the FBA fulfilment fee for all eligible units, directly affecting profitability.

With these recent updates, inventory management isn’t just a side task—it’s a core part of staying competitive.

Amazon’s changes are pushing sellers to optimise inventory in every aspect. High IPI scores, healthy stock levels, and strategic planning will ensure you’re not just avoiding fees but also maximising your profitability.

It’s clear: in 2024, effective inventory management can make or break your success on Amazon.

Top inventory mistakes Amazon sellers must avoid

#1: Overstocking inventory

Overstocking leads to serious issues.

It reduces your Inventory Performance Index (IPI) score. A lower score means less storage space in the future. Amazon rewards efficiency, not excess.

Excess inventory also costs you. Long-term storage fees add up quickly, especially if stock stays for more than 90 days. That money could be put to better use.

Holding too much inventory ties up your cash flow. Cash that could help with advertising, product launches, or improvements instead sits in Amazon’s warehouse.

The bottom line: don’t overstock.

Manage it efficiently. Save money. Boost your IPI.

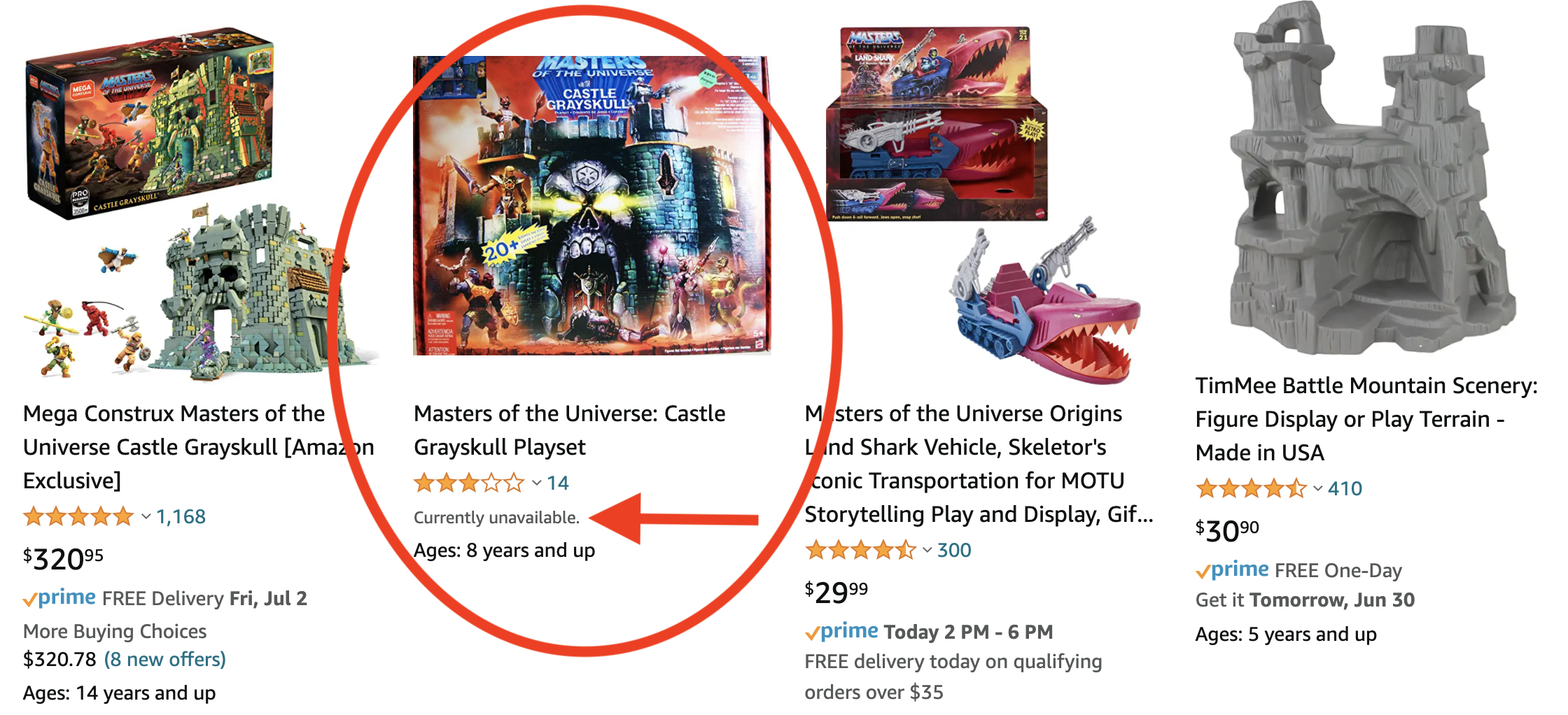

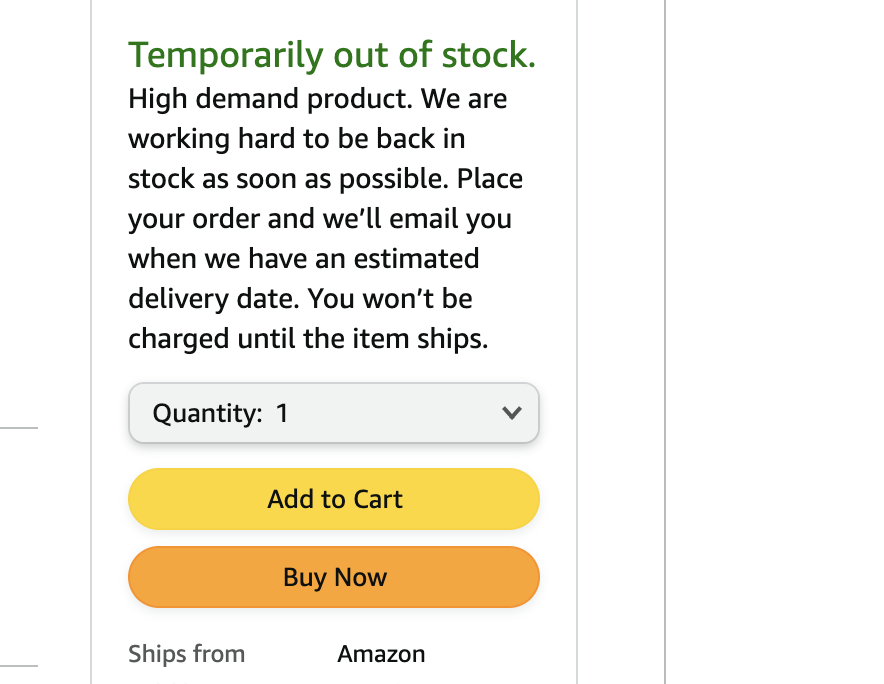

#2: Understocking and running out of stock

Running out of stock kills your momentum.

Customers go elsewhere. They buy from your competitors. Each day out of stock damages your Best Sellers Rank.

Amazon notices. It wants reliable products, always ready for customers. Stockouts tell Amazon you can’t meet demand, which means a drop in your organic ranking.

Returning to your previous position takes time. Competitors move ahead while you fall behind. Sales lost today are hard to regain tomorrow.

Keep enough inventory on hand. Stay consis78tent. Stay visible. Protect your ranking.

#3: Allowing inventory to become stranded

Stranded inventory is a costly mistake.

It sits in Amazon’s fulfilment centre but isn’t available for sale. You pay storage fees without getting anything in return. It’s wasted space and wasted money.

Stranded items also hurt your Inventory Performance Index (IPI). Poor IPI means lower inventory capacity and more limitations on growth.

Amazon provides the “Fix stranded inventory” tool. Use it regularly. Check for stranded stock and act fast.

Fixing stranded inventory saves money. It boosts IPI. It ensures your products are always ready for customers.

#4: Holding aged inventory

Holding aged inventory is a costly mistake.

Amazon charges fees for products stored longer than 271 days. After 365 days, those fees jump even higher. The longer your products sit, the more you pay.

Aged inventory also damages your IPI score. A lower score means less space for new products and limited growth opportunities.

To avoid fees, monitor inventory regularly. Use promotions to move slow-selling products before they age out. Clearing old stock frees up space and keeps your IPI healthy.

Don’t let inventory sit. Keep it moving.

#5: Neglecting perishable inventory

Neglecting perishable inventory leads to waste.

When products expire, you lose money. Spoiled items can’t be sold, and they take up valuable storage space. This impacts both your cash flow and profitability.

Amazon will still charge you storage fees for expired goods. And those fees add up.

You need to monitor expiration dates. Move older products quickly. Use promotions or discounts if necessary. Clear out items before they spoil.

Effective management of perishable inventory saves you money and prevents waste. Stay vigilant. Keep your stock fresh.

#6: Skipping regular inventory audits

Skipping inventory audits leads to problems.

Errors in your inventory build up without regular checks. Miscounts, missing items, or incorrect listings go unnoticed. Over time, these errors hurt your cash flow and damage customer trust.

Audits catch these mistakes early. Regular checks ensure your stock levels match what’s listed. They help you spot issues before they become costly.

Make auditing a habit. Schedule audits at least once a year—more often if possible. Accurate inventory is the foundation of a successful Amazon business.

Don’t skip it.

#7: Ignoring safety stock

Ignoring safety stock is risky.

Without a buffer, stockouts become inevitable. Unexpected spikes in demand or supplier delays leave you with empty shelves. Your sales stop, and your rankings drop.

Safety stock is your cushion. It helps you maintain availability even when supply chain issues arise. It prevents lost sales and keeps customers satisfied.

Calculate a reasonable safety stock level for each product. Keep it on hand. It’s better to have a little extra than to be completely out.

Don’t risk running out. Stay prepared.

#8: Failing to use inventory tools

Manual inventory tracking is a mistake.

It’s inefficient and prone to errors. Without tools, mistakes happen—miscounts, delayed reorders, and missed opportunities. Those errors affect your sales, ranking, and overall efficiency.

Inventory management tools automate the process. They track stock, forecast demand, and send alerts when it’s time to reorder. Tools help you save time, avoid mistakes, and keep your operations running smoothly.

Use inventory management software or hire Amazon selling consultants to do the same. It boosts efficiency, minimises errors, and keeps you ahead of the competition.

Don’t rely on guesswork. Use technology.

#9: Holding excess inventory too long

Excess inventory ties up your cash.

When stock sits for too long, it reduces liquidity—money that could be used for marketing or new products is locked away. Amazon charges long-term storage fees, especially when items exceed 90 days in storage.

These fees add up. The longer it sits, the more it costs you. Excess inventory also lowers your Inventory Performance Index (IPI), which affects how much space you’re allowed in Amazon’s fulfilment centres.

Reduce excess inventory. Run promotions. Improve cash flow and cut costs

#10: Ignoring seasonal trends

Ignoring seasonal trends means missed opportunities.

Demand changes during holidays and key shopping events. Not adjusting your inventory for these spikes can lead to stockouts or unsold products. Stockouts mean lost sales. Overstocking for slow seasons leads to high storage costs.

Analyse past sales data to predict peak times. Adjust inventory levels accordingly. Communicate with suppliers early to handle increased demand.

Proper planning for seasonal trends helps you maximise sales and avoid costly mistakes. Don’t let predictable patterns catch you off guard.

Stay ahead. Be prepared.

#11: Mishandling returns

Mishandling returns damage your bottom line.

Returns are part of the e-commerce experience. Failing to manage them properly impacts customer satisfaction and increases costs. Items returned without proper inspection or refurbishment end up as wasted inventory, draining your profit.

Effective returns management improves customer loyalty. Handle returns promptly. Inspect items. Restock or refurbish where possible. It’s not just about cutting losses—it’s about improving the customer experience.

A well-managed returns process saves money and keeps customers happy. Don’t ignore it.

Manage returns efficiently. Retain customers.

#12: Failing to track supplier lead times

Not tracking supplier lead times leads to costly mistakes.

You miss the right time to reorder. Inventory runs out before new stock arrives, causing stock outs and lost sales. Late shipments impact your availability, ranking, and customer trust.

Tracking lead times ensures smooth restocking. Monitor your supplier’s performance. Know how long production and shipping take. Plan ahead to avoid running out of stock.

A well-managed lead time means fewer delays and better inventory flow. Don’t let supplier delays surprise you. Stay informed and stay stocked.

#13: Failing to sync inventory across platforms

Failing to sync inventory across platforms is a critical error.

When inventory isn’t synchronised, overselling or stockouts become common. Selling products you don’t have results in cancelled orders and disappointed customers. Stockouts mean lost opportunities, lower rankings, and frustrated buyers.

Use inventory management tools that sync stock across all sales channels. Whether you sell on Amazon, eBay, or Shopify, accurate inventory tracking keeps you organised and prevents mistakes.

Synced inventory means satisfied customers and steady sales. Don’t let poor coordination cost you growth.

Stay synced. Stay successful.

#14: Not building relationships with suppliers

Weak supplier relationships hurt your business.

Suppliers are key players in your supply chain. If they don’t prioritise your orders, you face delays. Delays lead to stockouts, frustrated customers, and lost sales. Building strong relationships helps you secure better terms and faster fulfilment.

Communicate regularly. Pay on time. Show appreciation. A reliable supplier will prioritise your needs, ensuring consistent stock levels and fewer disruptions.

Invest in supplier relationships. It pays off in smoother operations, faster restocks, and better business stability.

#15: Ignoring your sell-through rate

Ignoring your sell-through rate is a missed opportunity.

Your sell-through rate tells you how well you’re balancing inventory and sales. A low rate means inventory is sitting unsold, wasting space and costing you money. Overstocking impacts your cash flow and reduces your Inventory Performance Index (IPI).

Track your sell-through rate. Optimise stock levels. Adjust ordering based on product performance to avoid tying up capital in slow-moving inventory.

A healthy sell-through rate means better cash flow, lower storage costs, and a higher IPI. Monitor it closely.

End inventory headaches, embrace success

Inventory management can feel overwhelming.

There are a lot of pieces to the puzzle, and each mistake can cost you more than you realise. Ignoring these issues will cost you time, money, and growth.

But the good news? You can change that. You can take control, make better choices, and keep your inventory optimised.

Start auditing regularly. Track lead times.

Monitor your sell-through rate. Build strong relationships with your suppliers. Stay ahead, stay prepared, and watch your business flourish.

When you master inventory management, you make room for growth. You maximise your profits. You ensure that your customers are never disappointed, and your rankings never drop.

It all comes down to action. Inventory isn’t just about counting stock—it’s about planning, growing, and securing your future.

Need help optimising your Amazon business?

At the eStore Factory, we understand what it takes to manage inventory the right way. Let our Amazon experts make inventory your strength, not your weakness.